Digital Twins Combine Enterprise Data And IoT To Drive New Business Value

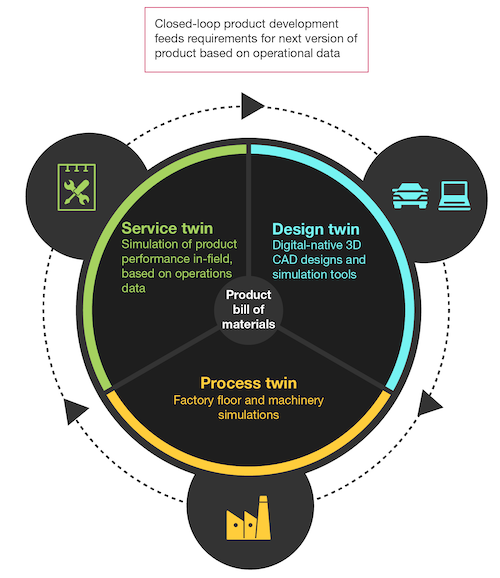

The digital twin is not a new idea: Designers and makers of machines have long recognized the value of being able to simulate those machines on a computer screen. But growing enthusiasm for connecting machines to the internet of things (IoT), and for delivering services instead of only selling products, mean that the digital twin is becoming relevant to a broader audience.

My latest report, “Untangle The Digital Twin As Part Of Your Digital Product Strategy,” explores the digital twin’s growing importance for designers, builders, operators, and maintainers of machinery. I will also be discussing these ideas in a webinar on November 13: Clients can subscribe here.

It’s certainly useful to have all of the engineering diagrams used to design a machine: They help you to operate and maintain that machine. In digital form, as a digital twin, you can manipulate them in different ways, make (or suggest) changes, and perhaps integrate them with similar resources for the other machines and assets that you need to manage.

Things get more interesting when you begin to add information about the way a specific machine is really used. This might include data on when, where, how, and by whom a machine is used, data on when and why parts were replaced, and more: IoT offers one useful source of this data, especially if integrated with parts databases, work order logs, etc. Digital twins can also combine design specifications, manufacturing details, operational data, a knowledge of physics, and machine learning to begin making predictions about future behavior: How might a specific jet engine, made from a known set of materials and maintained in a known way, behave when flown into a particular type of storm? How could the service regime be altered to increase reliability or decrease cost?

Much of the current work around digital twin remains within the control of a single vendor: They use digital twin as they design and build an asset, then use the same digital twin in partnership with their customer as that asset is put to work. The manufacturer gains an understanding of how the asset performs in the real world and creates opportunities to upsell spare parts and consumables or to offer predictive maintenance services. The customer gains greater understanding of how the asset works and may take advantage of value-added services from their vendor. But in most cases, the customer will see almost no integration between the digital twin of machine A (provided by vendor A) and the digital twin of machine B (provided by vendor B). The customer may also be constrained in how they can use the digital twin for themselves: Their contract with vendor A may explicitly prohibit them from sharing the data with vendor B or service provider C, despite the clear benefit to the customer of being able to do so. I’ll be digging into some of the issues here — and some possible solutions — in a further report later this year.

As always, Forrester clients can schedule an inquiry call to talk about this. Anyone can schedule a briefing.